CIRCBot

Part 3: Sensors & Output

This project accompanies Part 3 of Servo Magazine's series,

Beginner's Robotics on $50 a Month. It covers building the IR

sensors, the bump sensors and installing the LCD display.

The first part of the article can be found in the February issue of Servo

Magazine.

The Part 3 kit is available here.

Click here for

the Bascom source code used for CircBot (zipped).

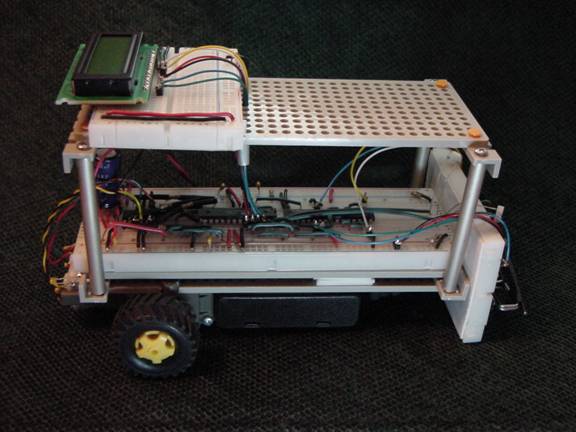

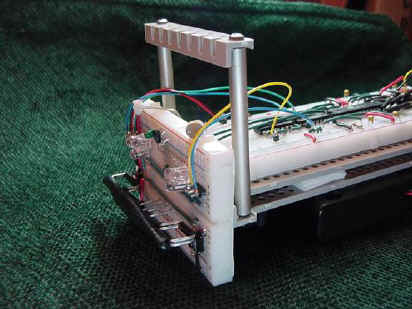

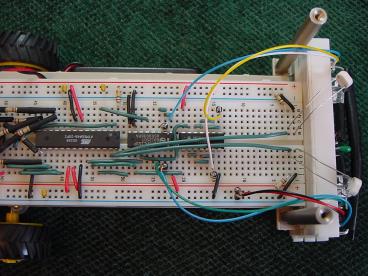

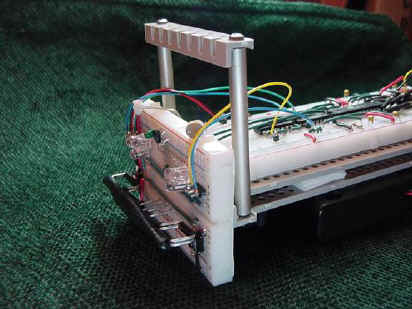

Main Board Connections

Click the image above to see a close up picture of

the main board wiring.

IR Obstacle

Sensor Circuit -

Part 2

IR test circuit that was

described in the magazine section of this article could be used as is for

a sensor. However, it would be

nice to get as much light out of the IR LED's as possible since that

would increase the range of the sensor.

The resistor used in the test circuit made sure that there was

enough load on the sensor's GL pin for the sensor to operate properly.

Replacing the resistor with two more IR LED's will keep the GL

pin loaded and will increase the amount of IR light.

Using the IR test circuit with three LED's would be sufficient

if all you wanted was to tell if there was something immediately in front

of the bot. However, it is

often useful to also be able to tell if the object in front of the bot is

more towards the left or right side of the bot.

For example, a sumo bot needs to turn toward an obstacle (i.e. the

opponent's sumo bot).

By

making two sets of IR lights and placing one set on each side of the

sensor, we can cause more light to be toward one side or the other of the

sensor's field of view by putting power to one set of lights or the

other.

You could use output pins form the microcontroller to power the

LED's. However, there is a limit to the amount of current a pin on the

microcontroller can source. Three

IR LED's will require more current than the microcontroller can provide.

If hooked directly to a microcontroller pin, they would cause the

power available to the rest of the chip to drop so low that the chip will

reset.

To get around this problem, we will use an inverter chip as a

buffer. The inverter will

limit the amount of current drawn from the microcontroller.

By running multiple inverters in parallel, we can increase the

amount of current available form the inverter to run the LED's.

The table in Figure 11 shows how to

wire a test circuit for the inverter.

Use the visible LED from the multiplexer test circuit to test the

output of the two-inverter chains. We'll

make the IR LED chains when we build the bump sensors in the next section.

|

Item

|

From

|

To

|

Notes

|

|

74HC04

Inverter Chip

|

F20

|

E15

|

Pin

1 @ F30 (chip faces backwards)

|

|

Wire

(GRN)

|

D14

|

D16

|

Length

5mm

|

|

Wire

(GRN)

|

C15

|

C17

|

Length

5mm

|

|

Wire

(GRN)

|

D17

|

D18

|

Length

3mm

|

|

Wire

(GRN)

|

G15

|

G17

|

Length

5mm

|

|

Wire

(GRN)

|

H16

|

H18

|

Length

5mm

|

|

Wire

(GRN)

|

G18

|

G19

|

Length

3mm

|

|

LED

|

A14

|

Upper

GND 14

|

Temporary,

remove after test

|

|

LED

|

J15

|

Lower

GND 15

|

Temporary,

remove after test

|

|

Test

Lead (RED)

|

Any

+V spot

|

Tester

board

|

Temporary,

remove after test

|

|

Test

Lead (BLK)

|

Any

GND spot

|

Tester

board

|

Temporary,

remove after test

|

|

Test

Lead (BLUE)

|

D19

|

Tester

board

|

Temporary,

remove after test

|

|

Test

Lead (GRN)

|

G20

|

Tester

board

|

Temporary,

remove after test

|

|

Wire

(GRN)

|

C19

|

G27

|

Length

30mm Install AFTER test

|

|

Wire

(GRN)

|

J20

|

J28

|

Length

20mm Install AFTER test

|

Figure

11 Inverter Wiring

The Bump Sensors

There will be objects that the

IR detector will not see. If a

material either absorbs IR or is transparent at IR frequencies, the IR

detector will not see it. Bump

sensors provide a method for your bot to sense these obstacles.

There are dozens of designs out there for making bump sensors.

They range from the simple to the complex.

On the simple end is a springy wire connected on one end to GND

with the other end terminating in mid-air just in front of a contact pad

which is wired to a terminal on the microcontroller (the terminal is also

connect to +5V through a 100 KW

resistor). When something

pushes the wire to contact the pad, the terminal on the microcontroller

goes from reading 5V to reading 0V. On

the complex end there are multi-lever linkages with molded parts that

surround a bot and activate different combinations of switches depending

on where contact is made.

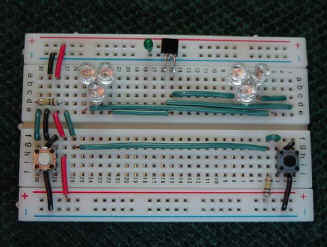

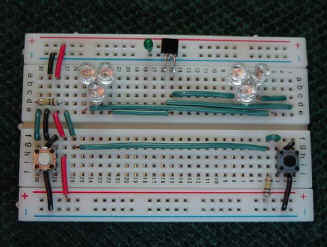

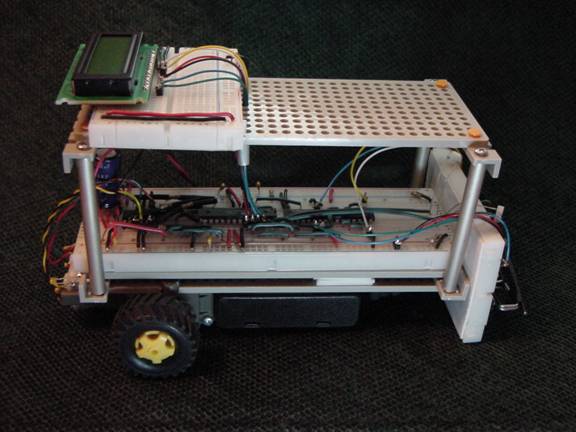

Figure 12

Front Breadboard

(Click to Image to View)

he bump sensors for this bot fall somewhere in between.

They use micro-switches which are pushed by a bumper made of

ceiling hanging wire and electrical tape.

It works, but with a little creativity, you should be able to come

up with better designs. Use

Google to search for bump sensor on the net for ideas.

We'll install the micro-switches and their circuitry first and

then make the actual bumpers. Figure

12 shows the small breadboard with the IR sensor, its LED chains,

and the bump switch circuitry. The

table in Figure 13 describes how assemble

the circuit in the previous figure.

|

Item

|

From

|

To

|

Notes

|

|

IR

LED

|

A5

|

A6

|

Neg

side at A6

|

|

IR

LED

|

A7

|

A8

|

Neg

side at A8

|

|

IR

LED

|

C6

|

C7

|

Neg

side at C7

|

|

IR

LED

|

A25

|

A24

|

Neg

side at A24

|

|

IR

LED

|

A23

|

A22

|

Neg

side at A22

|

|

IR

LED

|

C24

|

C23

|

Neg

side at C23

|

|

Small

Capacitor

|

Upper

+V 18

|

Upper

GND 18

|

|

|

IR

Sensor

|

See

|

Picture

|

GL

Pin 4 @ A15, Signal pin 2 @ A16

|

|

Wire

(GRN)

|

C15

|

C8

|

Length

17mm

|

|

Wire

(Grn)

|

D16

|

D1

|

Length

37mm

|

|

Wire

(GRN)

|

E15

|

E22

|

Length

17mm

|

|

Wire

(GRN)

|

E25

|

E3

|

Length

54mm

|

|

Wire

(GRN)

|

D5

|

D2

|

Length

7mm

|

|

Wire

(RED)

|

Upper

+V 28

|

A28

|

Length

10mm

|

|

Wire

(BLK)

|

Upper

GND 29

|

A29

|

Length

7mm

|

|

100

K resistor

|

D30

|

D28

|

Length

5mm

|

|

Wire

(GRN)

|

E30

|

F30

|

Length

7mm

|

|

Wire

(BLK)

|

E29

|

F29

|

Length

7mm

|

|

Wire

(RED)

|

E28

|

F27

|

Length

8mm

|

|

Wire

(GRN)

|

E27

|

F26

|

Length

8mm

|

|

Wire

(BLK)

|

F27

|

G26

|

Length

3mm

|

|

Wire

(BLK)

|

J29

|

Lower

GND 29

|

Length

10mm

|

|

Wire

(RED)

|

H27

|

Lower

+V 27

|

Length

12mm

|

|

Switch

|

G30

|

J28

|

Break

off center tab, face tab side to center

|

|

Wire

(GRN)

|

G26

|

G4

|

Length

54mm

|

|

Wire

(GRN)

|

F4

|

F3

|

Length

3mm

|

|

Wire

(BLK)

|

G2

|

F1

|

Length

4mm

|

|

Wire

(BLK)

|

Lower

GND 2

|

J2

|

Length

10mm

|

|

100

K Resistor

|

Lower

+V 4

|

J4

|

Length

7mm

|

|

Switch

|

G3

|

J1

|

Break

off center tab, face tab side to center

|

Figure

13 Front

Breadboard Wiring

You will need to make some jumper wires to connect the small

breadboard to the main board. Cut two 4-1/2 inch pieces from the six

stranded cable which was left over from building the programming cable in

last month's article. Slide

all of the wires out of the sleeves.

Cut one red and one black wire down to 2-1/2 inches.

Strip 9mm (about 1/4") off the ends of all the wires from one set

and off the ends of the blue wire from the other set.

Break off a set of four header pins from the strip of header pins.

Solder the wires to the pins in the following order: Blue, Black,

Red, Green. Break off another

set of three header pins. Solder

the following wires in order to these pins: White, Yellow, Blue.

Break off seven individual pins from the header strip.

Solder one to the other end of each wire you just attached to the

sets of pins.

Plug the set of three pins in to

the small breadboard in locations B1 through B3 with the blue wire in

position B1. Plug the set of

four pins in the locations B27 through B30 with the green wire in position

B27.

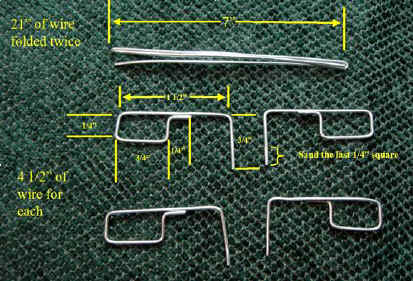

Now, we will bend the actual bumpers out of ceiling hanging wire.

The ceiling wire is fairly easy to bend into a desired shape using

pliers. It is also slightly

springy so it will return to its original shape after the bot backs away

from an object it has bumped. The

problem is keeping the ceiling wire bumper positioned over the

micro-switch so that it will press it when something makes contact with

the bumper. We will take

advantage of the fact that the breadboard holes are actually square.

The ceiling wire is 18 gauge, which is slightly larger than what

the holes can take. We will

sand an end of the wire square to fit the hole. This will keep the whole

piece form rotating.

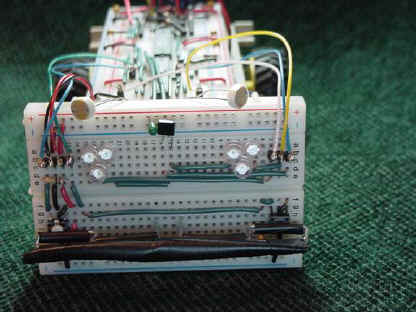

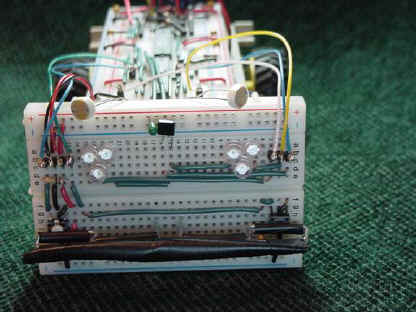

Figure 15

Completed Front Board

Figure 16 Standoffs for second level

However, the wire can still flex sideways.

To keep that from happening, we will double up the pieces and use

electrical tape to hold them together.

Figure 14 shows how to make the

individual pieces while Figure 15 shows

them assembled. Bending the

bumpers is a bit of an art. Take

your time bending the pieces. The doubled pieces have to match close

enough to be taped together

Attaching the Vertical

Breadboard

The flat of the angle piece on

the front of the CIRC Bot will be where the small breadboard will be

attached. Position the small

breadboard in front of the bot with the bottom of the board just above the

ground as shown in Figure 15.

On the back of the board, mark the area where the board is making

contact with the rest of the bot. Use

a knife to cut the wax paper which covers the double stick tape just the

area where the board will touch the rest of the bot.

Stick the board to the front of the bot.

Take the black and red jumper wires and attach them to convenient

locations on the lower +V (for the red) and GND (for the black) rails of

the main board. The blue wire

that is next to the black wire goes to I23, the green wire goes to I24,

the white wire goes to J15 and the yellow wire to A14.

Adding a Second Level to the CIRC Bot

We are quickly running out of

space on the CIRC Bot. To make

room for the LCD screen and for next month's parts, we need to add a

second level to the bot. Place

standoffs in the four outrigger holes as shown and attach two angles to

the top of the standoffs as shown in Figure 16.

Now use two-piece plastic rivets to attach a base plate to the top

of the angles. Take the logic

tester circuit apart and place its breadboard sideways on the top plate at

the back end of the bot with row one of the breadboard to the right when

looking from the back of the robot.

LCD Display Circuit

Header pins will need to be

installed in the fourteen holes along the top of the LCD.

Please refer to the datasheet for the LCD which can be found on the

Wright Hobbies website. NOTE

that there is some variation in the LCD's provided.

Some will have sixteen holes instead of fourteen.

You only need to add header pins to the first fourteen holes

starting at the hole closest to the edge (marked "1" on the

datasheet). Snap a strip of

fourteen pins from your header pins. Solder

the short end of the pins into the holes so that the long legs of the pins

are facing away from the LCD Screen.

The LCD will be installed on the second level so there will need to

be a number of wires run from the first level to the second.

Cut a 4-1/2 inch piece from the six stranded cable which was left

over from building the programming cable in last month's article.

Remove all but one inch of the outer sleeve.

Strip the ends of each wire. Break

off a set of four pins from the header strip.

Solder the following wires to those pin in this order: Red, Black,

Blue, Green. Break off another

two pins from the header strip. Solder

the remaining two wires, Yellow and White, to those pins.

Fish the unsoldered ends of the wires through the center hole in

the row of holes which is directly in front of the breadboard on the top

plate. Break off another set

of four pins and solder to them the other end wires which were soldered to

the other four pin strip. The

wires should be soldered in the same order: Red, Black, Blue, Green.

Finally, break off two single pins from the header strip.

Solder one of the pins to each of the remaining wires (Yellow &

White).

Wire up the LCD to the top breadboard as described in the table in Figure

17. Note that the

wiring table substitutes a small jumper for the potentiometer shown on the

schematic in the magazine portion of this article. In most cases, this

jumper will set the LCD contrast to the correct level.

However, if you wish to adjust the contrast, you can use the

potentiometer included in the kit. The

pins on the pot do not sit well in the breadboard so you will need to

solder a header pin to each of the pins on the pot if you decide to use

it.

|

Item

|

From

|

To

|

Notes

|

|

Wire

(BLK)

|

Front

GND 25

|

Main

Board (MB) Top GND 36

|

Length

65mm (twist with next wire)

|

|

Wire

(RED)

|

Front

+V 25

|

MB

Top +V 36

|

Length

65mm (twist with previous wire)

|

|

Jumper

(GRN)

|

MB

G33

|

F10

|

See

Text on Jumper Wires

|

|

Jumper

(BLU)

|

MB

G34

|

F11

|

See

Text on Jumper Wires

|

|

Jumper

(BLK)

|

MB

G35

|

F12

|

See

Text on Jumper Wires

|

|

Jumper

(RED)

|

MB

G36

|

F13

|

See

Text on Jumper Wires

|

|

Jumper

(YEL)

|

MB

C36

|

F18

|

See

Text on Jumper Wires

|

|

Jumper

(WHT)

|

MB

C35

|

F20

|

See

Text on Jumper Wires

|

|

Wire

(BLK)

|

Rear

GND 23

|

J23

|

Length

10mm

|

|

Wire

(BLK)

|

F23

|

F30

|

Length

17mm

|

|

Wire

(RED)

|

G22

|

G28

|

Length

15mm

|

|

Wire

(GRN)

|

G21

|

G29

|

Length

20mm

|

|

Wire

(BLK)

|

G19

|

G30

|

Length

27mm (add DOUBLE the normal stripped wire length)

|

|

Wire

(BLK)

|

Front

GND 1

|

Rear

GND 1

|

Length

45mm

|

|

Wire

(RED)

|

Front

+V 1

|

Rear

+V 1

|

Length

45mm

|

|

Wire

(Red)

|

Rear

+V 28

|

J28

|

Length

7mm (power to pot)

|

|

Wire

(BLK)

|

Rear

GND 30

|

J30

|

Length

10mm (GND for pot)

|

|

Wire

(GRN)

|

I28

|

I30

|

Length

3mm (substitute for pot)

|

|

LCD

|

H23

|

H8

(16 pin)

|

Pin 1 @ H23

|

Completed Top Level

Programming

As

with last month's article, sample code to test your new hardware can be

found both on the SERVO website and at http://www.wrighthobbies.net/guides/.

This month's program utilizes a timer interrupt.

A timer interrupt causes the program which it is in to stop what it

is doing and go do what is called out in the interrupt service routine

(ISR). Once the ISR is

completed, the program is returned to what it was doing before it was

interrupted.

You can use ISR's two ways. One

way is to put high priority actions in the ISR to make sure that they run

no matter what the rest of your program is doing.

For example, we could have put the sensor read routine and the

motor control case routine in the ISR.

This would have made sure that the sensors are read and their

information is acted upon at a regular interval.

The problem with that is that the length of time spent in the ISR

would be so long that it would be time to call the ISR again as soon as

the routing has ended.

This program uses a different approach where a low priority action

can only occur after the ISR has been called a certain number of times.

Inside the ISR is a counter that increments each time the ISR is

called. In the main program is

an IF statement that is true only after the counter has exceeded a certain

value. The true part of the IF

statement resets the counter and sends data to the LCD.

The rest of the main program is short and executes fairly fast when

the LCD is not called. In

fact, it executes so fast the LCD could not keep up if data was sent to it

each time the microcontroller cycled through main loop of the program.

The interrupt counter and the IF statement keeps the LCD refresh

rate down to an acceptable level and help speed up the rest of the main

code.

Variations

The

IR detector presented was about as minimalist as you can get.

Taking a look at the data sheet for the IS471F (http://www.junun.org/MarkIII/datasheets/IS471F.pdf),

we can see that there are a lot of different subsystems included in the

tiny sensor. David Cook's

Robot Room website has a page about building a modulated IR receiver out

of component parts http://www.robotroom.com/Infrared555.html

and another about building a transmitter http://www.robotroom.com/InfraredTransmitter.html.

Building these two circuits will give you a much better

understanding of what the IS471F is doing.

Sharp also makes the GP family of IR distance sensors which are very

popular in hobby robotics. Take

a look at http://www.acroname.com/robotics/info/articles/sharp/sharp.html

for a discussion of these sensors, how they work and how to interface them

to a microcontroller.

Pointing the IR sensor out from the robot makes it an object

detector. Pointing it down

makes it either a line follower or an edge detector.

Like with visible light, different materials reflect different

amounts of IR light. Most (but

not all) brands of black electrical tape reflect very little IR light

while white paper, white fiberboard, and Melamine all are highly

reflective in IR. This allows

a line follower to be built using one or more IR detectors.

For more information on line following, look at the article

"Line Following - A Guide to Using Sensors" in the guides'

section of the Wright Hobbies website.

When you using an IR detector facing forward as an obstacle sensor,

you want the bot to stop and turn when the sensor detects an object. When

you use it facing downward as an edge detector, you want the bot to stop

and turn when the sensor doesn't detect an object (i.e. the floor under

it). This is harder than it sounds since a single sensor in the front of

the bot near the centerline will only detect if the center of the front of

the bot is over the edge. It

wells you nothing about whether an edge is near the wheels.

I advise using a short table with pillows around it and a friend

standing on the other side of the table ready to catch the bot when you

try out your edge detection design.

IR transmitter / receiver pairs are also used to make wheel

encoders. The Seattle Robotics

Society has a good article on building an IR wheel encoder and using it

for "dead reckoning" or a robot's position on their website at http://www.seattlerobotics.org/encoder/200010/dead_reckoning_article.html.

There is a lot more to the bump switch.

Chris and Dawn Schur's bumper logic web page, http://www.schursastrophotography.com/robotics/bumperlogic.html,

goes into the benefits of a well thought out bumper design.

The micro-switches used in the bump sensors can also be used

as input devices. You can

modify the BASCOM program to display a menu on the LCD screen.

Use the left bump switch to go up the menu and the right switch to

go down. Add two more buttons

for enter and escape and you can create an interactive system on your bot.

Having such a system, you can create a program that allows the bot

to do different things based on what has been selected on the menu.

While the multiplexer chip does have a few ports left, you

will once again run out of usable ports if you try to do multiple ideas

from this section at one time. However,

if you look at the datasheet for the 74HC151, you will notice that there

is also a 16 to 1 version, the 74HC150. This chip will allow you to try

several of the variations suggested here.

It will require one more port on the microcontroller.

Do not use pins 2 or 3 (PD0 or PD1) on the microcontroller since

they will be needed next month. However,

pins 9 & 10 are also still available.

Conclusion

Your CIRC Bot is becoming more

complex. Last month, it had

the hardware necessary to seek or avoid light - based on how you

programmed it. This month, it

can also know when it has hit or is about to hit an obstacle.

If you strike out on your own and try some of the variations, it

can also be made capable of line following, edge detection, or dead

reckoning its position. By

mixing and matching the bits you have built on your CIRC bot and creating

the right code, you can make a bot that can do maze solving, sumo

wrestling, object retrieval, or line following.

Next month, you will learn how to free your bot of the limitations

of a single small microcontroller and give it the gift of "sight" with

scanning sonar.

|